Ulbrich Group is a traditional family-owned company in its third generation with headquarters in Austria and a strong network of subsidiaries in Germany, the Czech Republic, Slovakia, Hungary and Slovenia. Since 1949, Ulbrich Group has established itself as an expert in development and sales of high-quality hydraulic components, hydraulic systems and customized machinery. Ulbrich Group is also an established partner, e.g. in electronics and automotive sectors and offers solutions for customized lubricants, industrial adhesives, sealing compounds, robotics and PCB cleaning.

One unique selling point of Ulbrich in Austria is its expertise in custom machinery construction, particularly for the railroad industry, where efficient and innovative solutions have been developed for decades.

Ulbrich is contributing to a successful DACIO project by focusing on continuous research and profound expertise in the fields of hydraulics, electronics and mechanical engineering on the one hand and years of experience in the railroad sector on the other hand.

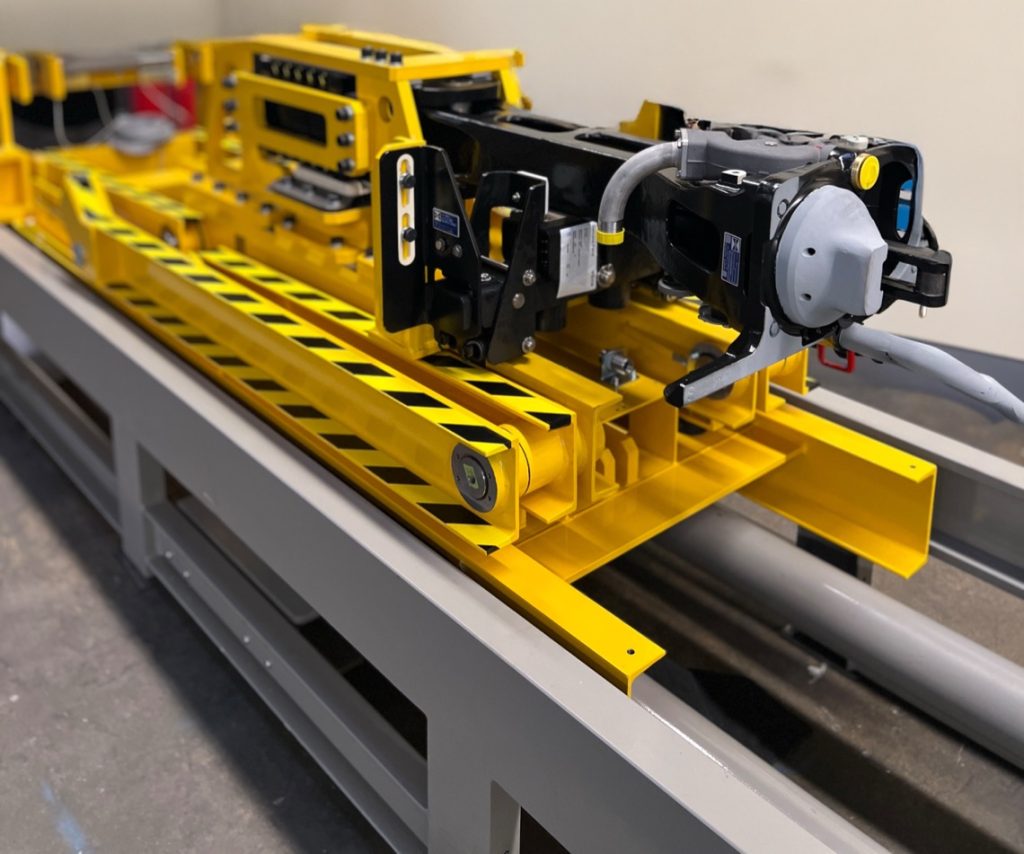

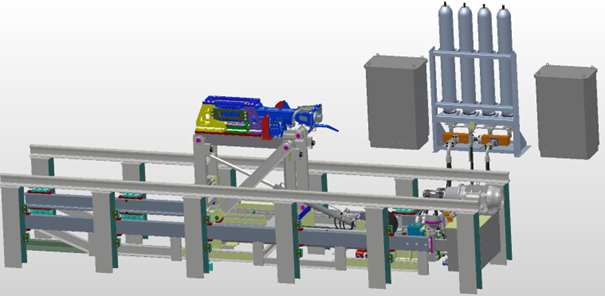

In cooperation with the railroad automation research group of FH OÖ, Ulbrich is involved in work package 5 in the development, design and implementation of a demonstrator for a “Full Digital Freight Train Preparator” (FDFT Preparator) for use in shunting yards.

The aim of this system is to provide an infrastructure-based solution with the ability to carry out a brake test during train preparation even without a locomotive. For this purpose, the system can fill the brake reservoirs of the individual wagons independently. The system also performs as a holding brake.

It can also brake slow-moving wagons – such as those that typically occur when running into directional tracks – in a targeted manner and bring them safely to a standstill. The wagons are secured in place to prevent unintentional movement. The system can brake groups of wagons with a total weight of up to 400 tons in a controlled manner. The system is permanently installed in a pit between the rails of a track.

Functional features of the system

Technical data:

Year of construction | 02/2025 |

Type series | 7P038724 |

Serial number | 7222007-1 |

|

|

Width | 1140mm |

Length | 8000mm |

Height | 2540mm |

Net mass | 6650kg |

|

|

Electrical schematic | 1ET38724 |

Supply cable | 4x 95mm² |

Supply voltage | 400V |

Electrical connected load | 32kW |

Fuse | 80A |

|

|

Hydraulic circuit diagram | 7P038724 |

Hydraulic oil | ISO VG 46 |

Total oil quantity | 320 L |

Oil temperature (max.) | 60°C |

Operating temperature | -15°C to +45°C |